Flotation Machine Used In Gold Ore

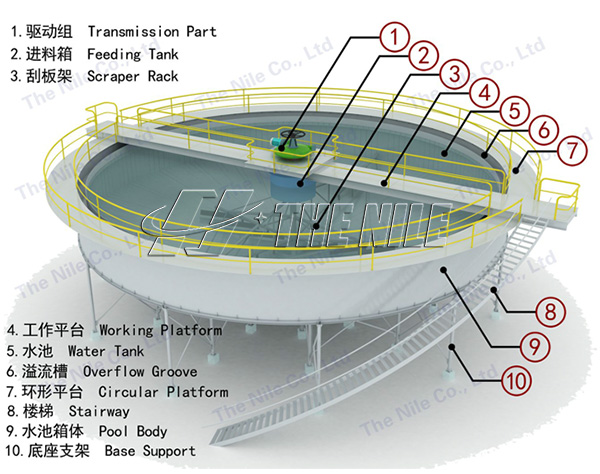

Flotation machine is short for flotation concentrator, referring to the mechanical equipment to complete the flotation process. In the flotation machine, after the addition of pharmaceutical treatment of the slurry, through the agitation of the inflatable, so that some of the mineral particles selectively fixed on top of the bubbles; float to the surface of the slurry is scraped to form a foam product, and the rest of the part of the slurry is retained in the slurry, in order to achieve the purpose of separating the minerals. There are many structural forms of flotation machine, the current commonly used mechanical agitation flotation machine.

Flotation machine is a floating mineral processing equipment, is one of the common equipment for chemical beneficiation, it is mainly through the cooperation with the flotation chemicals, so that the slurry with the help of the buoyancy of the bubbles to achieve the process of mining sorting.

In the whole flotation process, the flotation chemicals and the slurry to be selected into the flotation machine after mixing, after the flotation machine stirring and aerating effect, and then complete the contact between the bubble and the mineral particles, collision, adhesion and achieve the final mineralization, the purpose of the minerals with the bubbles up to reach the surface of the slurry to become a foam layer, that is, the formation of flotation concentrates, through the scraper or self-flowing way out of the flotation machine, the non-purpose minerals remain in the slurry area from the tank body discharged.

Working principle of flotation machine

The flotation machine drives the impeller to rotate through the motor triangle belt and transmission belt, which generates centrifugal effect and forms negative pressure. On the one hand, it inhales insufficient air to mix with the pulp, on the other hand, it stirs the pulp and chemicals, and at the same time, it refines the foam, so that the minerals are combined with the foam. Float to the surface of the pulp and form mineralized foam. Adjust the height of the gate to control the height of the liquid level, so that the useful foam is scraped out by the scraper.

Features of Flotation Machinery

The aeration and agitation of the slurry is accomplished by the impeller and mechanical mixing device of the flotation machine. It belongs to Self-absorbing flotation machine, generally of the upward suction type, i.e., air is inhaled near the mechanical stirring device in the lower part of the flotation tank.

This kind of flotation machine can not only self-absorb air, but also self-absorb slurry. It is easy to realize self-flow when returning ore, and has the advantages of less auxiliary equipment, neat equipment configuration, simple operation and maintenance. However, the machine has a small inflatable volume and large power consumption.

To summarize, among the various flotation machines, the mechanical agitation flotation machine is most widely used.

Performance

1. powerful mixing force can ensure the suspension of mineral particles with high density and large size, and can promote the dispersion and emulsification of insoluble chemicals.

2. For complex polymetallic ore sorting process, self-priming can rely on the suction of the impeller to realize the return of ore, without the need for large sand pumps.

3. In the case of difficult ore dressing, complex ore dressing or wishing to obtain high grade concentrate, it can ensure better stability index.

4. High rotational speed of moving parts, high energy consumption, serious wear and tear, and large maintenance.

Flotation machine is a floating mineral processing equipment, is one of the common equipment for chemical beneficiation, it is mainly through the cooperation with the flotation chemicals, so that the slurry with the help of the buoyancy of the bubbles to achieve the process of mining sorting.

In the whole flotation process, the flotation chemicals and the slurry to be selected into the flotation machine after mixing, after the flotation machine stirring and aerating effect, and then complete the contact between the bubble and the mineral particles, collision, adhesion and achieve the final mineralization, the purpose of the minerals with the bubbles up to reach the surface of the slurry to become a foam layer, that is, the formation of flotation concentrates, through the scraper or self-flowing way out of the flotation machine, the non-purpose minerals remain in the slurry area from the tank body discharged.

Working principle of flotation machine

The flotation machine drives the impeller to rotate through the motor triangle belt and transmission belt, which generates centrifugal effect and forms negative pressure. On the one hand, it inhales insufficient air to mix with the pulp, on the other hand, it stirs the pulp and chemicals, and at the same time, it refines the foam, so that the minerals are combined with the foam. Float to the surface of the pulp and form mineralized foam. Adjust the height of the gate to control the height of the liquid level, so that the useful foam is scraped out by the scraper.

Features of Flotation Machinery

The aeration and agitation of the slurry is accomplished by the impeller and mechanical mixing device of the flotation machine. It belongs to Self-absorbing flotation machine, generally of the upward suction type, i.e., air is inhaled near the mechanical stirring device in the lower part of the flotation tank.

This kind of flotation machine can not only self-absorb air, but also self-absorb slurry. It is easy to realize self-flow when returning ore, and has the advantages of less auxiliary equipment, neat equipment configuration, simple operation and maintenance. However, the machine has a small inflatable volume and large power consumption.

To summarize, among the various flotation machines, the mechanical agitation flotation machine is most widely used.

Performance

1. powerful mixing force can ensure the suspension of mineral particles with high density and large size, and can promote the dispersion and emulsification of insoluble chemicals.

2. For complex polymetallic ore sorting process, self-priming can rely on the suction of the impeller to realize the return of ore, without the need for large sand pumps.

3. In the case of difficult ore dressing, complex ore dressing or wishing to obtain high grade concentrate, it can ensure better stability index.

4. High rotational speed of moving parts, high energy consumption, serious wear and tear, and large maintenance.

Request for Quotation

You can get the price list and a NILE representative will contact you within one business day.

WhatsApp

WhatsApp E-mail

E-mail Chat Now

Chat Now