Ball Mill

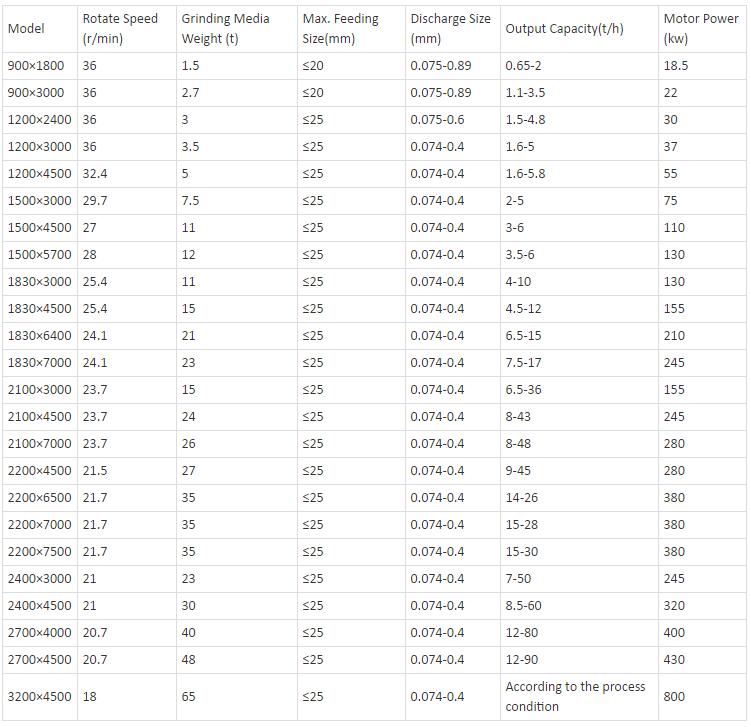

Ball mills are used primary for single stage fine grinding, regrinding, and as the second stage in two stage grinding circuits. According to the need of customers, ball mill can be either wet or dry designs. Ball mills have been designed in standard sizes of the final products between 0.074 mm and 0.4 mm in diameter.

Easy ways to get the answers you need. Service Online

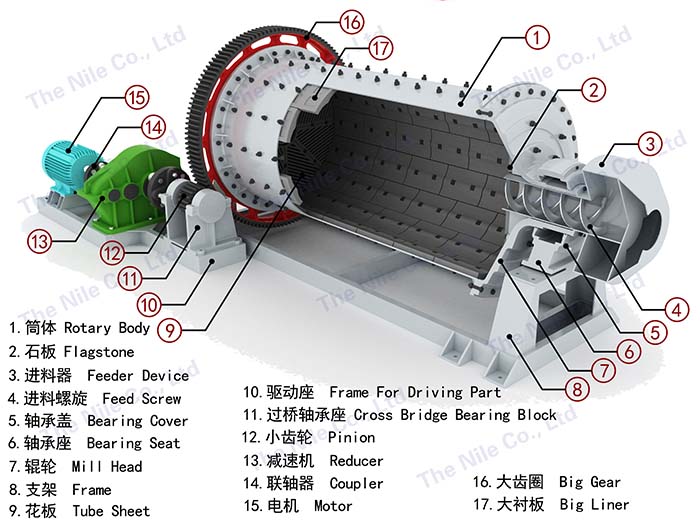

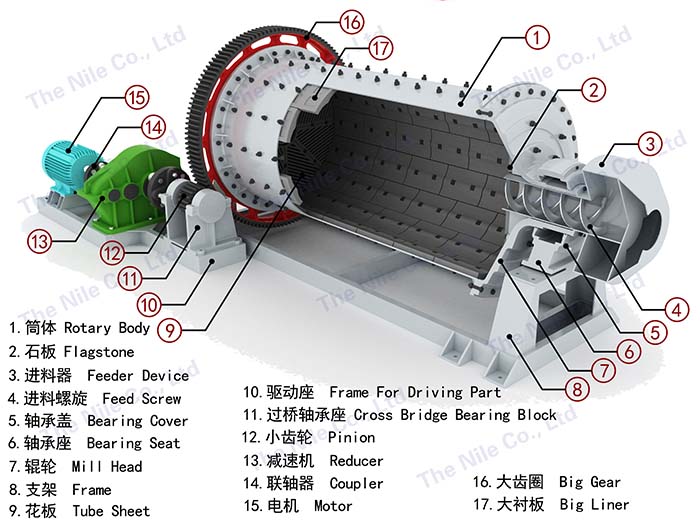

Ball Mill Working Principle

Ball Mill Motor drives the rotary cylinder through the rotation of reducer and surrounding large gear or it directly drives the cylinder with the rotation of surrounding large gear. The body of cylinder has installed appropriate grinding media - steel bars. They are raised to a certain height by centrifugal force and friction, and then fall down with the falling down or drain off state. Grinded materials are continuously given to the cylinder from the mouth, and then crushed by the movement of the grinding media. Finally, the materials will be discharged by the strength of overflow and continuous ore feeding so as to move to the next step.

Ball Mill Advantage

Ball Mill Motor drives the rotary cylinder through the rotation of reducer and surrounding large gear or it directly drives the cylinder with the rotation of surrounding large gear. The body of cylinder has installed appropriate grinding media - steel bars. They are raised to a certain height by centrifugal force and friction, and then fall down with the falling down or drain off state. Grinded materials are continuously given to the cylinder from the mouth, and then crushed by the movement of the grinding media. Finally, the materials will be discharged by the strength of overflow and continuous ore feeding so as to move to the next step.

Ball Mill Advantage

1.Suitable for grinding material with high hardness

2.The shape of the final products is circular

3.No pollution for the powder with ceramic ball

4.Stable performance Easy installation

5.The capacity and fineness can be adjusted by adjusting the diameter of the ball.

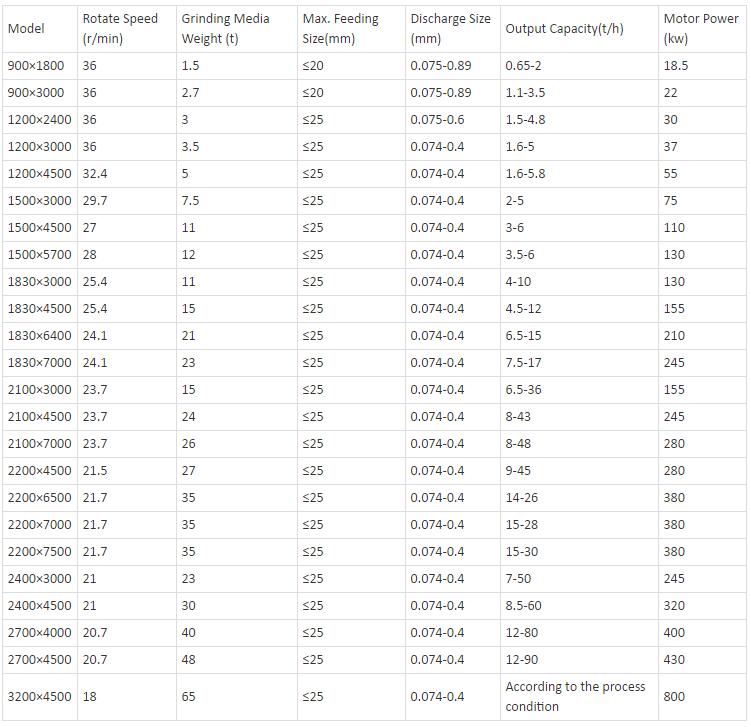

Ball Mill Technical Data

Request for Quotation

You can get the price list and a NILE representative will contact you within one business day.