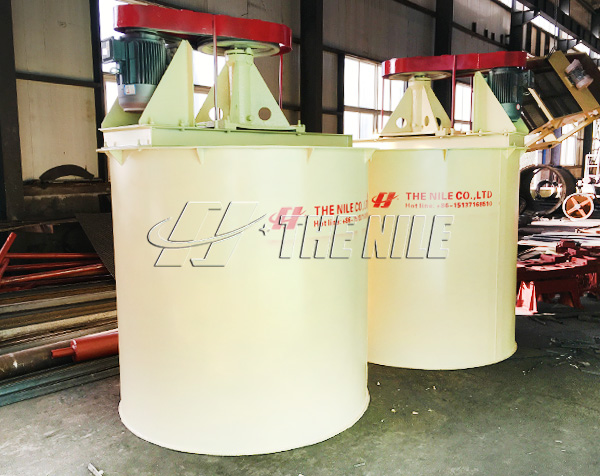

Magnetic Separator

Magnetic separator is one essential equipment in the ore dressing process which can separate raw materials with different magnetic rigidities

Easy ways to get the answers you need. Service Online

Product Description

Magnetic separator is one essential equipment in the ore dressing process which can separate raw materials with different magnetic rigidities.It is mainly used for screening the magnetic and non-magnetic material from the mineral powder and mineral pulp.The magnetic system of a magnetic separator is a compound of fine ferrite material and rare earth magnets.The average magnetic induction intensity of the surface of the cylinder is 100~600mT.

Main Type Sand Application of Magnetic Separator

1.Magnetic separator is suitable for the wet magnetic separation of the materials whose granularity is below 3mm such as magnetite, pyrrhotite, calcined ore and ilmenite and can also be used for removing iron from the materials such as coal, non-metal ore,and building material.

2.The permanent magnetic force tumbler is suitable for:

After medium and fine crushing, the magnetic pulley is used for eliminating the wall rock in the iron ore to improve the fineness.

To the un-deoxidized ore and send back for re-agglomeration.

To eliminate iron in the ceramic industry for improving the ceramic quality.

To eliminate iron in coal, foundry sand, refractory, and other industries.

Features

1.simple structure;

1.simple structure;

2.Easy-open structure gives a convenient cleaning;

3.large handling;

4.easy to operate;

6.The number of axial magnetic can be adjusted in accordance with material characteristics.

7.easy to maintain.

8.This magnetic separator is suitable for processing various bulk materials and will not be blocked for its compact structure;

9.Low power;

10.It also has a disaggregating function for sticky and poor-fluidity powders;

11.A stainless steel machine and full-closed operation enable an easy clean;

12.This high gradient magnetic separator has an optimized magnetic circuit,which offers a high-intensity magnetic field for a better separating effect;

13.Magnetic separator working under high temperature.

Working Principle

The pulp flows into the cell body from the pulp box, and under the water flow of the feeding spray pipe, the mineral grain will go into the feeding area of the cell body in the loose condition. In the magnetic field, the magnetic ore particles will have magnetic gathering and form magnet group or maget chain which is influenced by the magnetic forece inside the pulp and moves to the magnetic pole and finally is absorbed onto the cylinder.

The pulp flows into the cell body from the pulp box, and under the water flow of the feeding spray pipe, the mineral grain will go into the feeding area of the cell body in the loose condition. In the magnetic field, the magnetic ore particles will have magnetic gathering and form magnet group or maget chain which is influenced by the magnetic forece inside the pulp and moves to the magnetic pole and finally is absorbed onto the cylinder.

Technical Parameters

| Model | CTB612 | CTB618 | CTB712 | CTB718 | |

| Diameter(mm) | Φ600 | Φ600 | Φ750 | Φ750 | |

| Length of drum(mm) | 1200 | 1800 | 1200 | 1800 | |

| Granularity(mm) | 0-0.4 | 0-0.5 | |||

| Feed density(%) | 20-25 | ||||

| Capacity | Dry ore(t/h) | 10-15 | 15-20 | 30-35 | |

| Pulp(m³/h) | 10-15 | 15-20 | 30-35 | ||

| Power(kw) | 2.2 | 3 | |||

| Weight(kg) | 1200 | 1500 | 1830 | 2045 | |

| Overall dimensions(mm) | 2550*1300*1250 | 3150*1300*1250 | 2770*1780*1600 | 3350*1780*1600 | |

Request for Quotation

You can get the price list and a NILE representative will contact you within one business day.