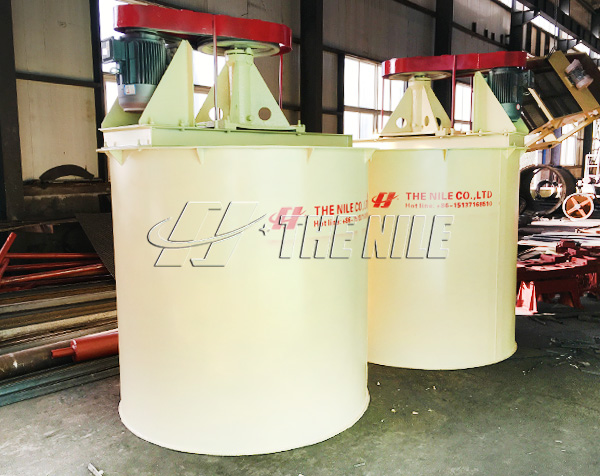

Double impellers leaching stirred tank

Double impeller leaching and stirring tank is a cyanide leaching and stirring equipment designed with reference to international advanced technology.

Easy ways to get the answers you need. Service Online

Product description

Double impeller leaching and stirring tank is a cyanide leaching and stirring equipment designed with reference to international advanced technology. This equipment is mainly suitable for gold leaching, adsorption and other mixing operations with small specific gravity, low viscosity, slow sedimentation speed, ore particle size of -200 mesh and more than 90%, and slurry concentration of less than 45%. It has the characteristics of double-layer impeller, uniform stirring, low energy consumption, long service life, and even aeration. It is deeply favored by customers who has gold processing mines.

Advantages

The flow of the ore stream is stable, the slurry is mixed uniformly, and the power consumption is low;

The air enters the groove through the hollow shaft of the transmission, and is agitated by the blades, so that the air is evenly dispersed;

Compact structure and easy maintenance;

The hollow shaft is ventilated to the bottom, and air enters the tank through it, dispersed evenly with small bubbles;

Using two new impellers, the diameter of the impeller of the stirring tank is large, the rotation speed is low, and the power consumption of the stirring is small, which can reduce the wear of the char;

The stirring intensity is moderate, and the concentration and fineness distribution of the slurry in the tank are consistent, which can improve the leaching rate of cyanide and the adsorption rate of carbon;

The impeller of the leaching mixing tank is lined with wear-resistant rubber, which has a low speed and a long service life.

Working principle

When the double impeller leaching mixing tank is working, the pulp will flow from the top to the bottom under the drag and stirring action of the double impeller, diffuse through the surrounding damping plate, and feed air at the lower end of the shaft to mix with the pulp Circulate upward to form a uniform suspension mixture.

Technical date

| Double impellers leaching stirred tank | |||||||||||

| Model | Cell(diameter×Height)(mm) | Effective Volume(m³) | Impeller | Diameter(mm) | Cyclical Planetary Reducer | Weight(kg) | |||||

| Rotation Speed(rpm) | Diameter(mm) | Feeding Tube | Output Tube | Model | Ratio | Motor Power(kw) | Cell Weight | Total Weight | |||

| SJ2.0×2.5 | 2000×2500 | 6 | 52 | 909 | 2-φ133 | 2-φ133 | XLD2.2-4-29 | 29 | 2.2 | 1609 | 2144 |

| SJ2.5×3.15 | 2500×3150 | 13 | 52 | 935 | 2-φ125 | 2-φ125 | XLD2.2-4-29 | 29 | 2.2 | 2398 | 3095 |

| SJ3×3.15 | 3000×3150 | 18.9 | 43 | 1130 | 2-φ150 | 2-φ150 | XLD4-5-35 | 35 | 4 | 2480 | 4160 |

| SJ3.55×4.0 | 3550×4000 | 35 | 43 | 1310 | 2-φ150 | 2-φ150 | XLD4-5-35 | 35 | 4 | 4260 | 5025 |

| SJ4.0×4.5 | 4000×4500 | 48 | 35 | 1750 | 2-φ150 | 2-φ150 | XLD7.5-7-43 | 43 | 7.5 | 6397 | 7569 |

| SJ4.5×5.0 | 4500×5000 | 71.6 | 35 | 1750 | 2-φ159×6 | 2-φ159×6 | XLD7.5-7-43 | 43 | 7.5 | 8614 | 10864 |

| SJ5.0×5.6 | 5000×5600 | 98 | 31 | 2046 | 2-φ159×8 | 2-φ159×8 | XLD11-8-47 | 47 | 11 | 8740 | 14291 |

| SJ5.5×6.0 | 5500×56000 | 112 | 31 | 2100 | 2-φ159×8 | 2-φ159×8 | XLD11-8-47 | 47 | 11 | 12467 | 18745 |

| SJ6.5×7.0 | 6500×7000 | 195 | 21 | 2400 | 2-φ159×8 | 2-φ159×8 | GRF147-Y22-4P-70.87 | 47 | 22 | 17890 | 25978 |

| SJ7.0×7.5 | 7000×7500 | 245.4 | 21 | 2400 | 2-φ159×8 | 2-φ159×8 | XLD22-10-47 | 47 | 22 | 20505 | 29030 |

| SJ7.5×8.0 | 7500×8000 | 268.6 | 23 | 2900 | 2-φ168×8 | 2-φ168×8 | XLD22-10-47 | 47 | 22 | 22552 | 32796 |

| SJ8.0×8.5 | 8000×8500 | 319 | 18.5 | 3300 | 2-φ168×8 | 2-φ168×8 | TPS315-3F | 59 | 22 | 30559.5 | 42467.3 |

| SJ8.5×9.0 | 8500×9000 | 395 | 18.5 | 3300 | 2-φ219×8 | 2-φ219×8 | TPS315-3F | 59 | 22 | 34130 | 46623 |

Request for Quotation

You can get the price list and a NILE representative will contact you within one business day.