Energy Saving Ball Mill

Ball mills are used primary for single stage fine grinding, regrinding, and as the second stage in two stage grinding circuits. According to the need of customers, ball mill can be either wet or dry designs. Ball mills have been designed in standard sizes of the final products between 0.074 mm and 0.4 mm in diameter.

Easy ways to get the answers you need. Service Online

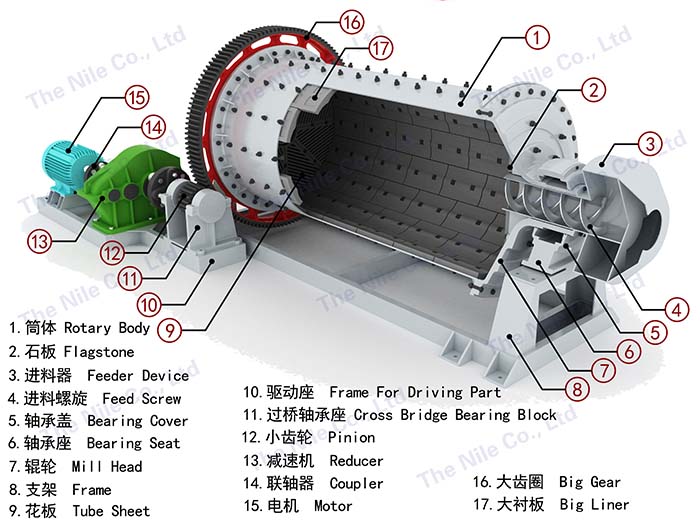

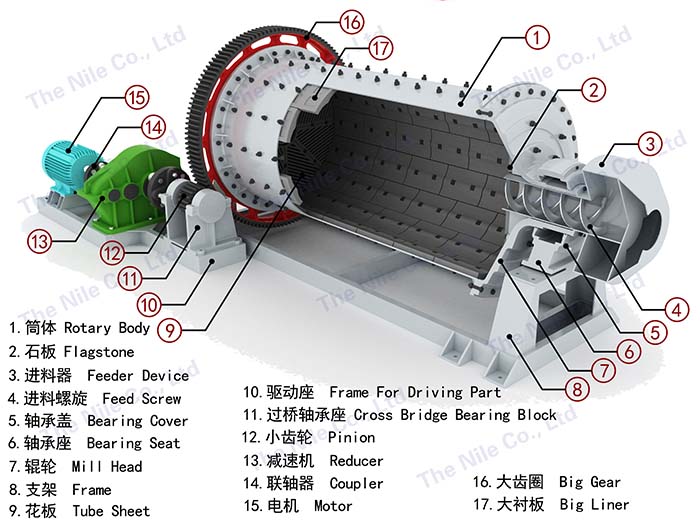

Ball Mill Working Principle

Ball Mill Motor drives the rotary cylinder through the rotation of reducer and surrounding large gear or it directly drives the cylinder with the rotation of surrounding large gear. The body of cylinder has installed appropriate grinding media - grinding mill balls or steel bars. They are raised to a certain height by centrifugal force and friction, and then fall down with the falling down or drain off state. Grinded materials are continuously given to the cylinder from the mouth, and then crushed by the movement of the grinding media. Finally, the materials will be discharged by the strength of overflow and continuous ore feeding so as to move to the next step.

Ball Grinding Mill Machine Advantages

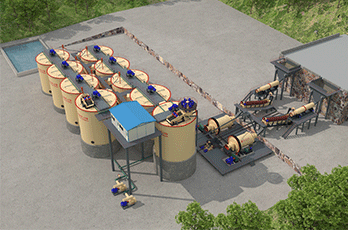

Gold mining ball grinding mill machine working and factory video

Ball Mill Motor drives the rotary cylinder through the rotation of reducer and surrounding large gear or it directly drives the cylinder with the rotation of surrounding large gear. The body of cylinder has installed appropriate grinding media - grinding mill balls or steel bars. They are raised to a certain height by centrifugal force and friction, and then fall down with the falling down or drain off state. Grinded materials are continuously given to the cylinder from the mouth, and then crushed by the movement of the grinding media. Finally, the materials will be discharged by the strength of overflow and continuous ore feeding so as to move to the next step.

Ball Grinding Mill Machine Advantages

1.Suitable for grinding material with high hardness

2.The shape of the final products is circular

3.No pollution for the powder with ceramic ball

4.Stable performance Easy installation

5.The capacity and fineness can be adjusted by adjusting the diameter of the ball.

Energy Saving 900×1800 Ball Mill Grinding Machine for Gold Processing Plant Price from Factory

1. The thickness of cylinder end flange is 45mm, with high concentricity and low failure rate.

2. All the fixed bolts are made of high strength bolts, and equipped with PU pad and iron pad to stop leakage.

3. Bigger size grinding head and main bearing, the main bearing life is not less than 5 years.

4. The cross-sectional area of the inlet and outlet is increased by 50%, thickness of the feeding tube is up to 12mm, its service life can reach 15-18 months.

5. Thickened ten-byte coupling with flexible eight-hole disc to reduce the failure rate of the transmission part.

6. High manganese and thickened liner, wet grinding life can reach more than 3 years.

7. To use of the third generation of energy saving motor, power consumption is reduced 20% at least.

Gold mining ball grinding mill machine working and factory video

| Model | Balls Weight | Max. Feeding Size | Capacity | Output size | Motor Power | Weight |

| (t) | (mm) | (t/h) | (mm) | (kw) | (t) | |

| Φ900*1200 | 1 | 20 | 0.5-1.5 | 0.074-00.4 | 18.5 | 4 |

| Φ900*1800 | 1.5 | 20 | 1.1-3.5 | 0.074-00.4 | 22 | 4.8 |

| Φ900*3000 | 2.6 | 20 | 1.5-4.8 | 0.074-00.4 | 30 | 6 |

| Φ1200*2400 | 3.5 | 20 | 1.6-5 | 0.074-00.4 | 30 | 9.5 |

| Φ1200*4500 | 6.5 | 20 | 1.6-5.8 | 0.074-00.4 | 45 | 13.1 |

Request for Quotation

You can get the price list and a NILE representative will contact you within one business day.

WhatsApp

WhatsApp E-mail

E-mail Chat Now

Chat Now